The Evolution of Manufacturing: From Labor-Intensive to AI-Driven

Manufacturing has undergone a profound transformation, evolving from labor-heavy processes to tech-driven automation. The rise of artificial intelligence (AI) is reshaping industries, particularly through human-machine collaboration. One standout example is OpenAI’s influence on smart manufacturing, creating a future where production is more efficient, cost-effective, and streamlined.

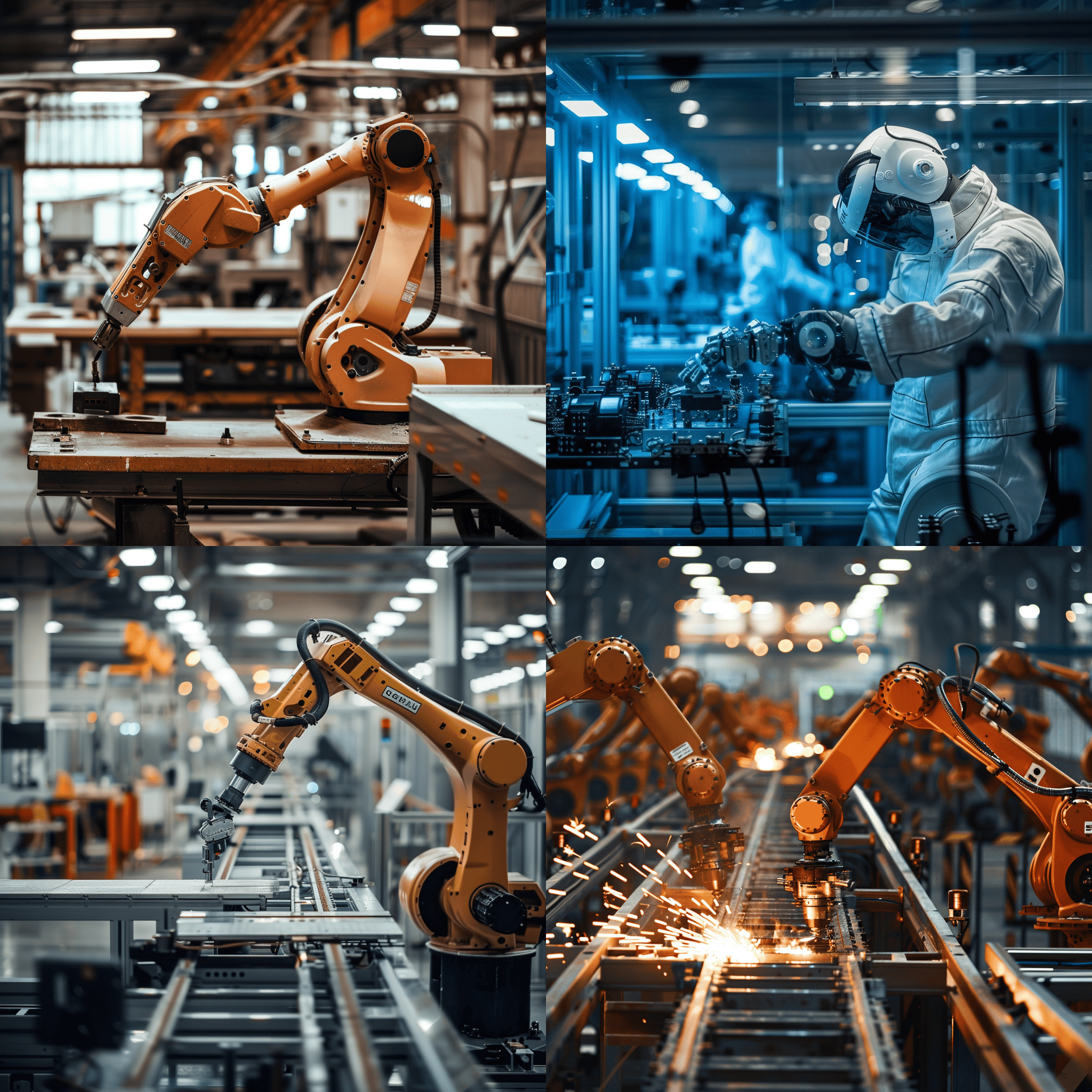

The Shift: From Human Labor to AI-Driven Processes

In the past, manufacturing was predominantly human-dependent, leading to inefficiencies such as:

- Resource Wastage

- Production Delays

- Operational Uncertainties

These inefficiencies increased costs and reduced profit margins. However, the introduction of AI is transforming this landscape by addressing these challenges head-on. Here are some key areas where AI has made an impact:

Increased Productivity

AI-driven systems optimize manufacturing processes by minimizing resource wastage and boosting efficiency. According to McKinsey, AI adoption in manufacturing could enhance productivity by up to 40%.

Cost Reduction

AI-powered automation reduces labor costs, errors, and energy consumption. A study by Deloitte suggests that AI can cut manufacturing costs by up to 20% through better resource management and automation.

Enhanced Quality Control

AI technologies like sensors and motion detection systems enable more precise sorting and error detection, leading to better quality control and less waste.

AI systems are not replacing human labor but enhancing it by integrating intelligent machines that detect motion, weight, and sensory data to streamline processes and reduce downtime.

Key Impacts of AI on Manufacturing

- Advanced Sensory and Motion Detection

AI-driven sensory systems facilitate precise material sorting and packaging, ensuring quality and minimizing errors. - Efficient Resource Management

AI monitors raw material usage, reduces waste, and provides valuable insights that help manufacturers forecast profit margins accurately. - Cost Savings

By optimizing processes, AI helps reduce operational costs. The Boston Consulting Group estimates a 15-30% reduction in manufacturing costs through AI-driven automation. - Predictive Maintenance and Reduced DowntimeAI-powered predictive maintenance uses machine learning to analyze equipment data and predict when machinery is likely to fail. This minimizes unplanned downtime and reduces the need for emergency repairs. By analyzing patterns in machine performance, AI can schedule maintenance at optimal times, ensuring smooth operations. According to a report by PwC, predictive maintenance powered by AI can reduce equipment downtime by 30-50% and extend the life of machines by 20-40%.

Revolutionizing Packaging Manufacturing with Technology

The packaging manufacturing sector has witnessed substantial improvements due to technological advancements, particularly AI integration. Packaging, once reliant on human input, is now largely automated, leading to fewer errors, more streamlined production, and reduced resource waste.

Key Benefits of Technology in Packaging

- Automation of Processes

AI-powered machines handle most of the packaging tasks, reducing human error and increasing efficiency. PwC reports that automation in packaging can reduce waste by 25% and boost production speed by 20%. - Optimized Resource Utilization

AI systems in packaging track raw materials, manage inventory, and forecast demand with greater accuracy, reducing waste and improving margins. - Cost Efficiency

Automated packaging processes lower labor costs while enhancing quality. According to Grand View Research, the global intelligent packaging market is projected to reach $40 billion by 2025, driven by demand for efficiency and cost reduction.

Why Choose Packaa as Your Manufacturing Partner?

When selecting a manufacturing partner, factors like integrity, innovation, and reliability are key. Packaaa embodies these values and more, helping clients meet their packaging goals through technological innovation.

Why Packaaa Stands Out

- Commitment to Innovation

We stay ahead of industry trends by integrating the latest technologies and packaging solutions. - Customer-Centric Approach

Our flexible, cost-effective solutions are tailored to meet the budgetary needs of diverse businesses without compromising quality. - Proven Expertise

With a proven track record of successful projects, Packaaa is the reliable partner you need for your packaging solutions.

Let’s shape the future of packaging together. For more information, contact us via email at contact@Packaaa.com or WhatsApp at +86 181 0020 3843.